In this blog, Phil Bolus, our General Manager, contemplates what the future might hold for a controls company workforce facing new technical challenges such as integration and IoT. He also explains how Essential Control have designed their E-Magine BeMS system to cope with these challenges from an engineering and a user’s perspective.

The labour cost of delivering a complex Building Management System today is rising faster than the price of fuel on the forecourts and this is creating a culture in the industry of “Dutch auctioning” and inflated remuneration packages. Couple this with an age demographic that is getting frighteningly older and a skillset requirement that is becoming more and more complex and the BeMS industry has a perfect storm approaching.

Apprenticeships in the controls world are few and far between and most of those that are offered are not bespoke enough to the industry which puts employers off from taking on younger trainees. The BCIA and FETA are addressing this through skills workshops and influencing training providers etc. and this can only be good for the future however there are other ways that will complement the apprenticeship route.

The labour market has some rich sources of skilled people and these are typically found in:

Both these sources of labour are ideal in our experience for many reasons however the main ones are:

An agile controls business will have to rethink its HR strategy around labour resourcing and how it sets up its training programmes. More thought will need to go into the skillsets that are really required rather than simply replacing like for like. All too often a pay structure is too rigid meaning that the only way an engineer can earn more money is to take on a promotion that may not be suitable. This pay structure should allow for rewarding additional training and the taking on of additional responsibilities like field sales and supervision without the need for the engineer to move too far away from his/her core skillset. If these responsibilities finish then the additional sum could be removed. A company will have to understand the value of its engineering team and not deviate from a pay structure once set.

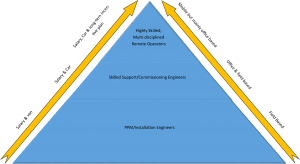

Companies could introduce tiered grading schemes that permanently recognise and reward loyalty & effort from their staff and most importantly, when an engineer is at the top of the grading structure, have a method of giving them rewards for taking on extra duties without having to chase promotion. Fig 1.0 shows what could be done with a team to lower cost base and promote people however traditionally this is inverted with a larger, skilled and expensive field based team. Whilst it certainly isn’t my position to suggest that this is a perfect model, it does go some way towards addressing cost and retention issues in a business.

Fig 1.0

In general, freely programmable systems are great for flexibility but often introduce a higher skillset requirement with more training and ultimately a higher cost base.

At Essential Control we design and manufacture a different kind of BeMS that offers all the complexity of a freely programmable system but de-skills the configuration using smart tools and automatic configuration of site schematics and control strategies. E-Magine is designed to take the complexity out of the whole sell/install/commission cycle and allow VAR’s to concentrate their expensive, experienced labour on the tasks that add the most value to their business. We have identified more than ninety control applications and plant variations and packaged them into configurations that can simply be selected and dropped into the system. Control strategies, connection diagrams and commissioning sheets are instantly created thus eliminating the need for extended engineering times. Whilst schematics are not automatically created it is a small step to produce impressive results by utilising a control palette to drag and drop the relevant symbols onto the screen. All the point links are automatically transferred.

Should you want to get into the nitty-gritty of the control strategy and do some extra fine tuning then our comprehensive E-Site software allows you to do just that and, when you have finished, transfer the changes seamlessly to the controller.

Combining modern, open protocols such as ModBus and BACNet with resilient industrial ones such as CANBus, the E-Magine system can sit happily on its own or within an equally open system. This approach gives the client access to many of its unique mobile “E-Apps” that allow users at any level to easily understand what the control system is doing. This common approach also allows us to make all our sites analytics ready with little or no requirement for tagging to be done, as the point labels follow the Haystack Project guidelines.

BACNet compliance allows us to be flexible with our I/O configuration and enables us to make use of third party, low cost modules that cater for the greater point input demands being placed on the control system.

Fig 2.0

All E-Magine systems require a Cloud connection and this is because the controllers can be remotely interrogated, programmed & commissioning support given to the site engineers. This approach also allows us to monitor and support the system into the future offering first time fix rates of more than 87%. These features, plus many others allow us to offer a full control solution that is simple and easy to install, programme and maintain.

But the simplification shouldn’t stop at the install/commissioning stage, many customers find these systems too complex to dedicate too much time operating them especially when their primary tasks become too numerous and prevent them from spending time learning how to drive the BeMS. Essential Control have a range of mobile E-Apps that give simple clear indication of key site information and allow group changes of parameters to cut down time spent changing multiples schedules and setpoints.

Fig 3.0

The future is not about adding complexity into the installation, programming and use of these systems, it is about de-skilling these tasks and focussing on the meaning of the data you retrieve from them.

Phil Bolus

Essential Control General Manager